Develop an efficient food production line that will protect your margins, increase your yield, and allow you to gain full traceability across your production operation. We are experts in productivity management solutions for food manufacturing operations and can assist with optimizing your raw product intake, processing, and packaging.

Our equipment, software and support solutions all aim to provide a customized and flexible food processing operation. We are here to help you by selecting the right solutions, optimizing, and supporting your automation requirements.

To extract the most value out of our equipment solutions, MARCO North America provides software modules to control, track, and report on process productivity every step of your operation. These modules provide the ability to incentivize staff and provide a fair and manageable bonus scheme based on actual performance. This helps boost productivity and maximize your labor force. Manufacturers utilizing our software solutions benefit from:

To extract the most value out of our equipment solutions, MARCO North America provides software modules to control, track, and report on process productivity every step of your operation. These modules provide the ability to incentivize staff and provide a fair and manageable bonus scheme based on actual performance. This helps boost productivity and maximize your labor force. Manufacturers utilizing our software solutions benefit from:

Control yields, monitor operators, and track line performance with our yield optimization software. Gather and review live yield data from RTE products, fresh produce, and any other food processing operation to keep pack weight on target to deliver up to 30% improved productivity and line performance.

De-skill the formulation process for baked goods, vegetable mixes, pharmaceuticals, and cosmetics with guided prompts that ensure strict adherence to the template recipes. The software includes health and safety notifications that help keep operators compliant while reporting on product consumption, cycle time, and individual operator data across the formulation process.

Display your MARCO Trac-IT® information on large screens around the facility to keep production staff informed at all times. Our production data displays help to maintain compliance with PPE, provide guidance on specific packing operations, and can show company videos that include training materials like what defects to look for when onboarding new agency staff. This includes a direct link to our Trac-IT modules to automatically populate live data.

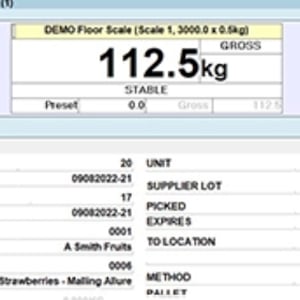

Easily book in new raw materials from suppliers and track the process to ensure maximum yield based on goods received. Monitor waste and product quality through the processing line and enforce quality control (QC) procedures (FIFO and compliance/grading requirements) on any new products with additional warehouse management features.

Digitize paper processes to track and monitor your quality control procedures throughout the facility. The QC module integrates with the Yield Control (YCM) and Goods Received (GRM) solutions to generate insights into your entire production process, helping to identify and rectify any deficiencies quickly and maintain maximum productivity.

Verify barcode information including LOT or batch details, use-by dates, date coding, product-specific nutritional information, or any other critical information that’s required on the label. Validate that each product has the right label and avoid shipping any units without the required information included on the label.

Incorporate all our software solutions into a line-wide, manufacturing execution system for end-to-end solutions, including YCM, QCM, GRM, and recipe formulation. Track your entire production process from a single source, using live data from all your current operations.

Along with our solutions, we provide extensive training and support throughout the process. MARCO North America can provide on or off-site training, including remote assistance when required. As part of our support network, you can get price reductions on spare parts and priority status on our servicing and calibration services.

To find out more about our training and support services, get in touch with MARCO North America.

MARCO remains a global leader in food processing and manufacturing productivity solutions. Along with our industry partners, we provide tailor-made solutions that help reduce waste to <2.5% and increase productivity by 30%. Monitor and control all your processing operations with our integrated systems that support food manufacturers in over 40 countries.

To evaluate your current giveaway percentages or discuss your productivity losses with an expert, reach out to MARCO North America today.

MARCO North America provides complete operational traceability that delivers 30% productivity improvement and reduces waste to less than 2.5%. We offer end-to-end, modular hardware systems for food processing operations with integrated software control solutions.

To see how we can help improve your productivity and reduce waste, get in touch and we’ll help you evaluate your current operation’s giveaway percentages and the potential savings.

The combination of durable equipment solutions with traceable software enables increased productivity and efficiency for food manufacturers handling, processing, and packaging products such as fresh produce, convenience foods, red meat, poultry, and seafood products.