Trusted By Industry Leaders

Over 1,000 systems installed for global food producers and manufacturers

Complete Turnkey Conveyance Systems

We provide design, engineering, the conveyors and controls, plus installation, commissioning, and start-up of the new system in your facility

Design & Engineering

- Complete system design and layout

- Mechanical and electrical engineering

- Controls and programming

- Integration planning

Manufacturing & Installation

- State-of-the-art manufacturing facility

- Quality control and testing

- Professional installation team

- Commissioning and start-up support

One stop shop for conveyor systems

NCC Automated Systems is truly a one-stop shop for everything you need related to conveyor systems and integration. No coordination between multiple vendors - we handle it all. Schedule Your Free ConsultationTurnkey System Solutions

We provide design, engineering, the conveyors and controls, plus installation, commissioning, and start-up of the new system in your facility

Conveyor Systems

Non-sanitary conveyor systems for any unitized or loose product, from cases and cartons to small manufactured products

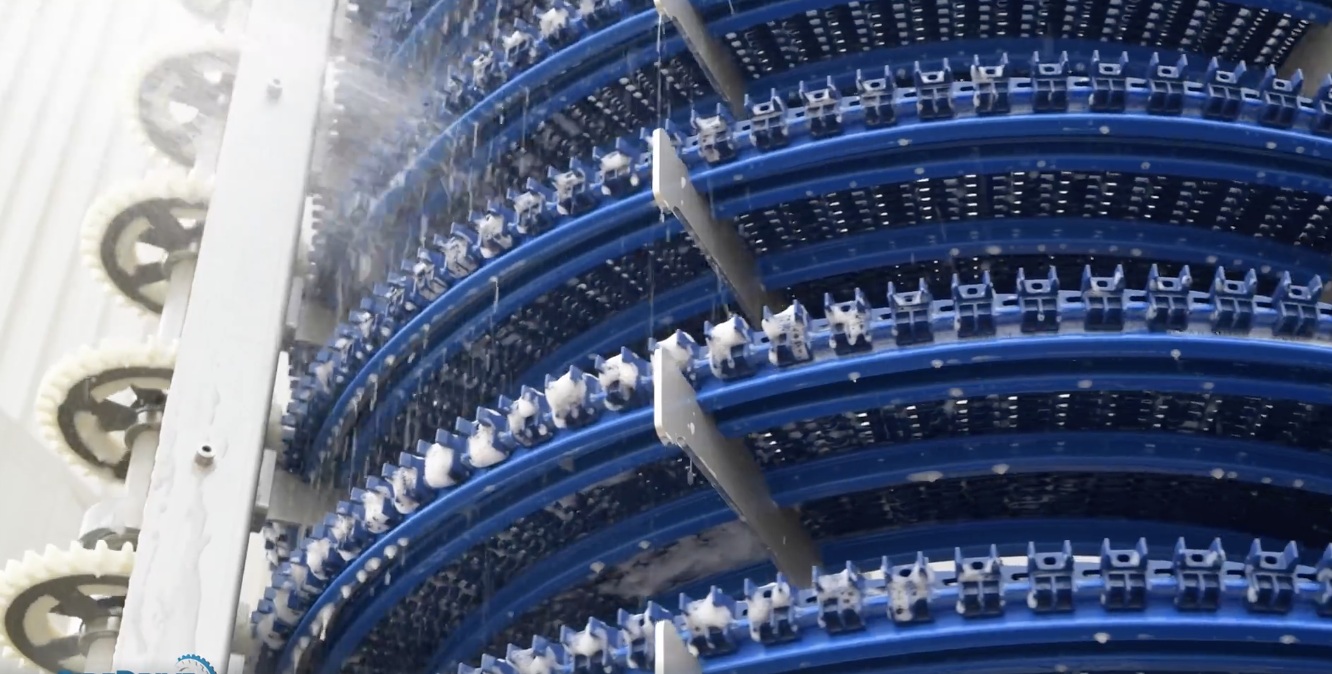

Sanitary Conveyor Systems

Full selection of sanitary food conveying components for special product handling and turnkey sanitary systems

Packaging Line Integration

Complete system engineering and installation for integrated packaging lines into your plant

Ophthalmic Automation Systems

Non-sanitary conveyor systems for any unitized or loose product, from cases and cartons to small manufactured products