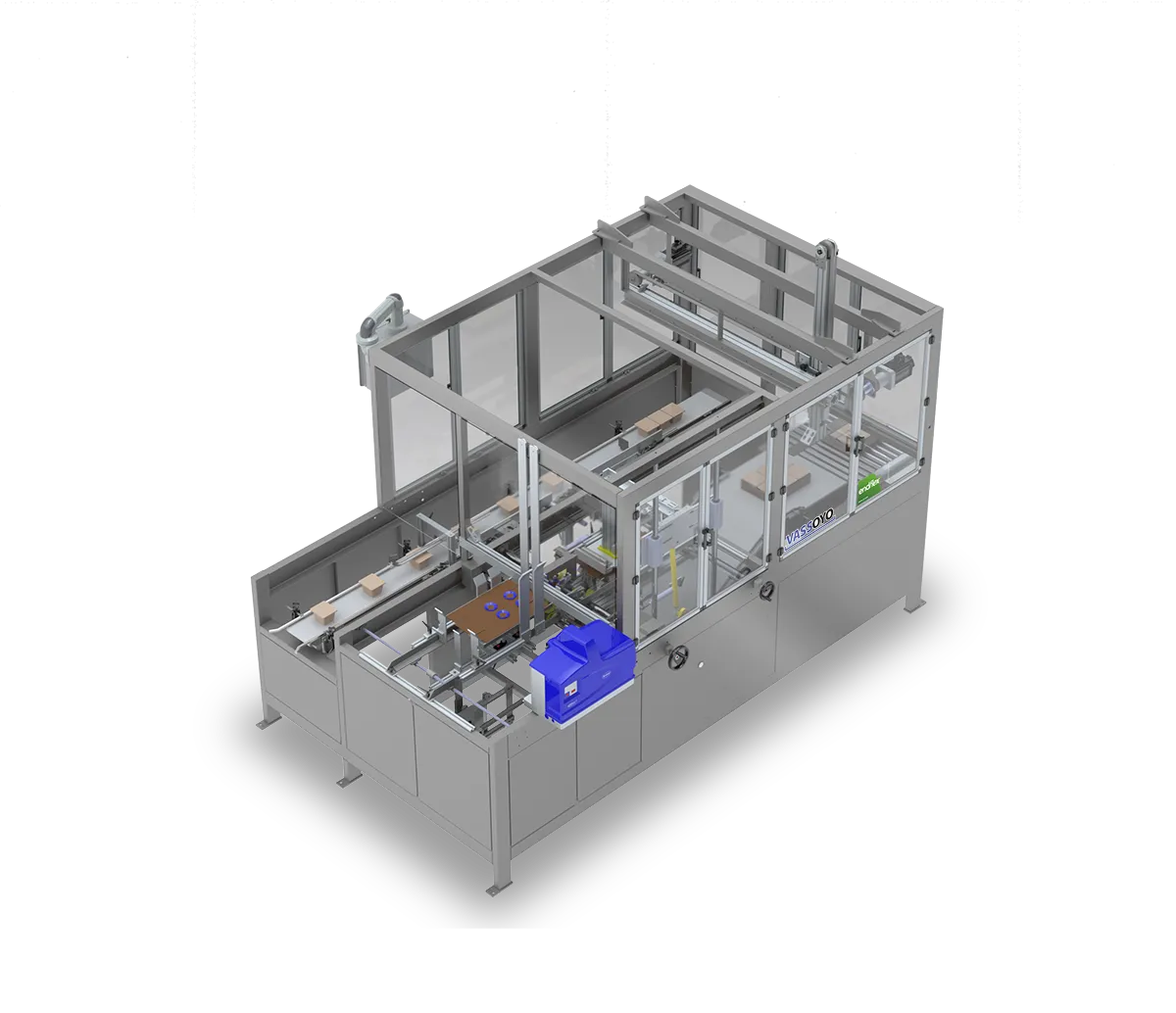

VASSOYO ALL-IN-ONE

TRAY FORMER / LOADER / SEALER

This All-In-One Automated Tray Packing System streamlines packaging operations by fully automating the entire tray formation and product loading process.

-

Automated Tray Formation: The system mechanically extracts individual blanks from a hopper, accurately folds them, and applies glue to major and minor flaps. An automated tray former then erects trays of various sizes and configurations using hot-melt glue. This process ensures careful handling of tray materials to preserve high-quality graphics and aesthetics for retail display.

-

Versatility: This versatile system accommodates a wide range of tray styles commonly used across diverse industries, including toys, gaming, auto parts, hardware, consumer goods, and food products.

-

Automated Product Loading: The integrated modular robotic cell efficiently top-loads products into the formed trays, completing the automated packaging process.

Videos

Features

- Heavy duty, welded tubular steel frame

- Color touch screen user interface allowing adjustment of glue patterns and full access to all functions & timing of machine and troubleshooting

- Product staging and loading area

- All electric controls

- 24 VDC control voltage

- Detail operation and maintenance manual

VASSOYO ALL-IN-ONE

TRAY FORMER / LOADER / SEALER

This All-In-One Automated Tray Packing System streamlines packaging operations by fully automating the entire tray formation and product loading process.

-

Automated Tray Formation: The system mechanically extracts individual blanks from a hopper, accurately folds them, and applies glue to major and minor flaps. An automated tray former then erects trays of various sizes and configurations using hot-melt glue. This process ensures careful handling of tray materials to preserve high-quality graphics and aesthetics for retail display.

-

Versatility: This versatile system accommodates a wide range of tray styles commonly used across diverse industries, including toys, gaming, auto parts, hardware, consumer goods, and food products.

-

Automated Product Loading: The integrated modular robotic cell efficiently top-loads products into the formed trays, completing the automated packaging process.

Videos

Features

- Heavy duty, welded tubular steel frame

- Color touch screen user interface allowing adjustment of glue patterns and full access to all functions & timing of machine and troubleshooting

- Product staging and loading area

- All electric controls

- 24 VDC control voltage

- Detail operation and maintenance manual