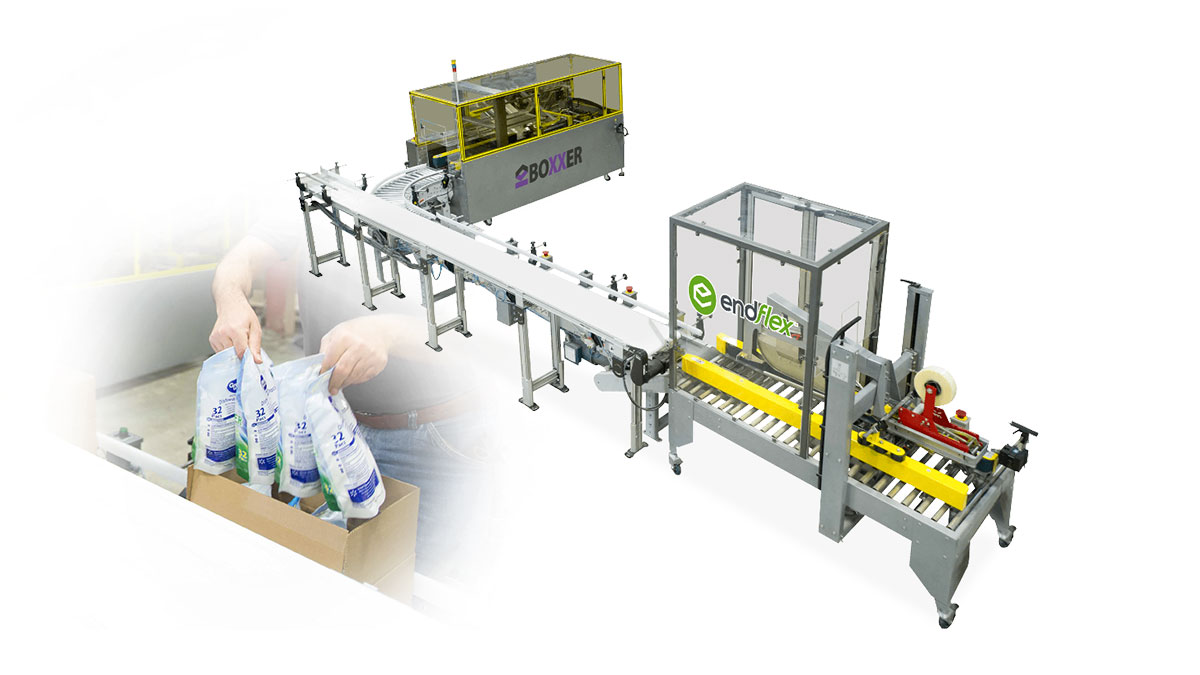

SEMI-AUTOMATIC CASE PACKER

Automatic Case Forming & Taping with Hand Load

The manual assisted packing station combines case erecting, hand packing, and tape sealing into a single, compact, and highly efficient work cell. This ergonomically designed system features an automatic indexing feature that positions both cases and product for optimal operator comfort, effectively minimizing repetitive wrist and arm motions. Ultimate flexibility is provided by variable speed product infeed, on-demand case presentation, and the availability of 1, 2, 3, or 4 operator stations. The system easily accommodates a wide variety of product sizes, shapes, weights, and materials, which can be quickly and easily packed into a large range of case sizes.

Videos

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer

SEMI-AUTOMATIC CASE PACKER

Automatic Case Forming & Taping with Hand Load

The manual assisted packing station combines case erecting, hand packing, and tape sealing into a single, compact, and highly efficient work cell. This ergonomically designed system features an automatic indexing feature that positions both cases and product for optimal operator comfort, effectively minimizing repetitive wrist and arm motions. Ultimate flexibility is provided by variable speed product infeed, on-demand case presentation, and the availability of 1, 2, 3, or 4 operator stations. The system easily accommodates a wide variety of product sizes, shapes, weights, and materials, which can be quickly and easily packed into a large range of case sizes.

Videos

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer