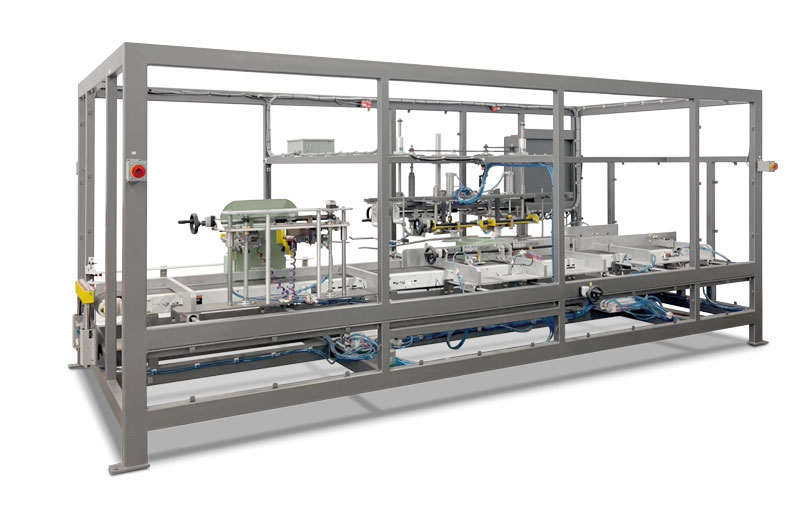

POPLOK TRAY CLOSER

automatic lidded tray closer

Achieve complete automation of your tray handling and sealing with this tray closing solution, designed to seal lidded trays with superior precision and high efficiency. The system utilizes an automatic incoming tray control gate that ensures every tray enters the unit with the short side facing forward, thereby optimizing the sealing sequence.

The process begins as the tray dust flaps are folded 90 degrees and neatly secured inside the tray structure. As the package advances to the subsequent station, integrated plow bars smoothly guide the lid into its closed position. For the final closure, the front lip minor flaps are gently folded and securely inserted into the front slots. A concluding compression station then applies the necessary pressure to finalize the precise sealing of the front flap.

Videos

Mechanical:

• Heavy duty, “Steel it” painted, mild steel frame

• Pneumatic system– FRL (Filter, regulator, lubricant)

• Safety interlocked doors and safety guarding all around machine

sides

• Automatic incoming tray control gate

• Trays enter system “short-side” leading

Electrical & Software:

• Omron PLC with color touchscreen HMI

• HMI Changeover guidance with visuals

• Nema-4 electrical enclosures

• Advanced security settings and user control

• Storage of up to 100 recipes

• Automatic triggers and alerts

• Jam detection logic

POPLOK TRAY CLOSER

automatic lidded tray closer

Achieve complete automation of your tray handling and sealing with this tray closing solution, designed to seal lidded trays with superior precision and high efficiency. The system utilizes an automatic incoming tray control gate that ensures every tray enters the unit with the short side facing forward, thereby optimizing the sealing sequence.

The process begins as the tray dust flaps are folded 90 degrees and neatly secured inside the tray structure. As the package advances to the subsequent station, integrated plow bars smoothly guide the lid into its closed position. For the final closure, the front lip minor flaps are gently folded and securely inserted into the front slots. A concluding compression station then applies the necessary pressure to finalize the precise sealing of the front flap.

Videos

Mechanical:

• Heavy duty, “Steel it” painted, mild steel frame

• Pneumatic system– FRL (Filter, regulator, lubricant)

• Safety interlocked doors and safety guarding all around machine

sides

• Automatic incoming tray control gate

• Trays enter system “short-side” leading

Electrical & Software:

• Omron PLC with color touchscreen HMI

• HMI Changeover guidance with visuals

• Nema-4 electrical enclosures

• Advanced security settings and user control

• Storage of up to 100 recipes

• Automatic triggers and alerts

• Jam detection logic