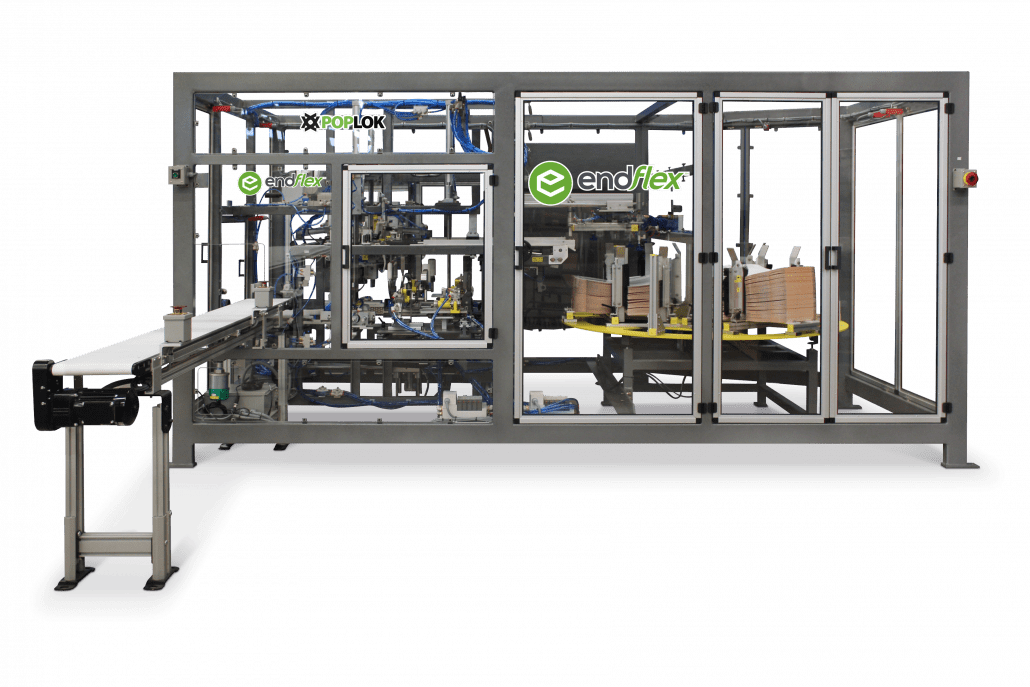

POPLOK INSERTER

Carton Tray Forming

Our advanced fold-and-tuck tray former with display inserter is engineered for the most complex carton forming applications. It is commonly used in the pharmaceutical, medical device, beauty, health, and consumer electronics industries.

How Fold and Tuck Carton Forming Works:

The machine pulls tray blanks, one at a time, from the hopper. It then pulls the blank through forming plows, erecting the side and end panels of the tray while folding in the minor flaps. When the tray reaches the bottom of its vertical travel, a set of pneumatically controlled bars fold and lock the rollover flap in place. The finished tray is then indexed into position for the insert. The insert blank is picked from its own hopper, folded and formed, before a plunger pushes it down and precisely places it into the formed tray.

Videos

Features:

- 1, 2, 3, 4 tuck or multi ‘”fold & tuck” models available

- Form large or small trays with or without a lid

- Eliminate repetitive motion issues and insurance claims

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Auto-idler

- Venturi vacuum technology used in tray erection

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- On-line detailed operation manual accessible through HMI

POPLOK INSERTER

Carton Tray Forming

Our advanced fold-and-tuck tray former with display inserter is engineered for the most complex carton forming applications. It is commonly used in the pharmaceutical, medical device, beauty, health, and consumer electronics industries.

How Fold and Tuck Carton Forming Works:

The machine pulls tray blanks, one at a time, from the hopper. It then pulls the blank through forming plows, erecting the side and end panels of the tray while folding in the minor flaps. When the tray reaches the bottom of its vertical travel, a set of pneumatically controlled bars fold and lock the rollover flap in place. The finished tray is then indexed into position for the insert. The insert blank is picked from its own hopper, folded and formed, before a plunger pushes it down and precisely places it into the formed tray.

Videos

Features:

- 1, 2, 3, 4 tuck or multi ‘”fold & tuck” models available

- Form large or small trays with or without a lid

- Eliminate repetitive motion issues and insurance claims

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Auto-idler

- Venturi vacuum technology used in tray erection

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- On-line detailed operation manual accessible through HMI