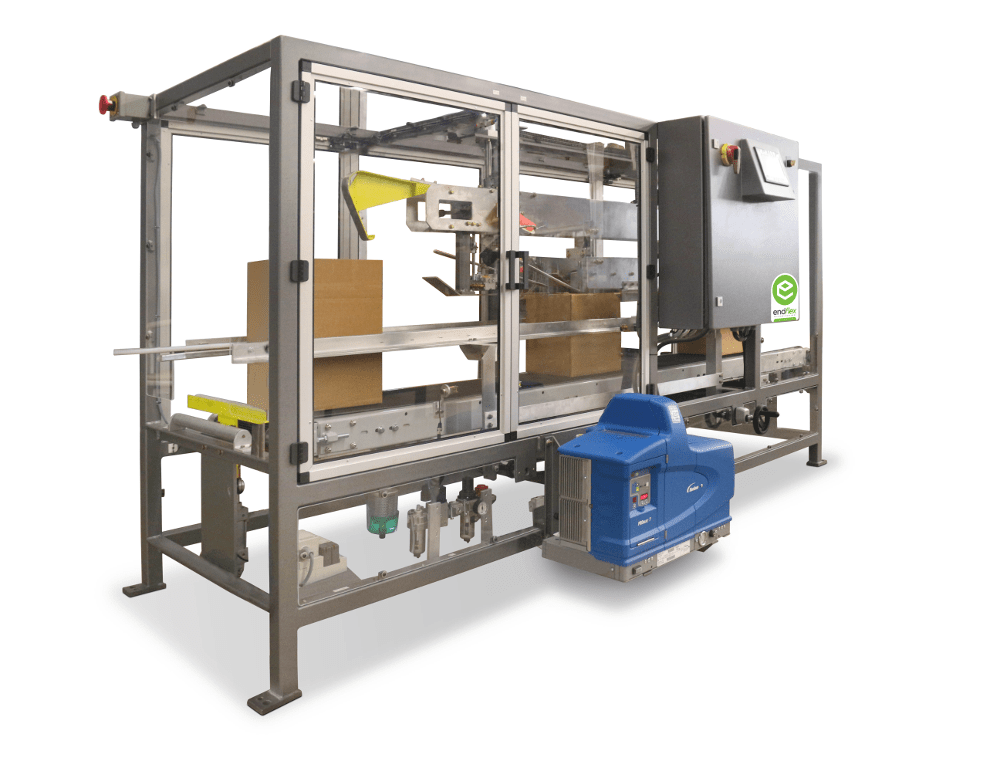

EZ-GLUE

HOT MELT GLUE CASE OR TRAY SEALERS

Our EZ-Glue case and tray sealing equipment is designed to receive an erected, loaded box and securely seal the top using hot melt adhesive. The process begins when the case indexes from the conveyor and is positioned by a box stop before entering the machine. As the box transfers through the unit, the front and rear minor flaps are first tucked in. Hot melt glue is then applied to these minor flaps simultaneously as the major flaps are folded over the top of the case. Finally, the sealed case passes beneath a set of compression rollers to ensure a strong, permanent bond on the case top.

Videos

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute

EZ-GLUE

HOT MELT GLUE CASE OR TRAY SEALERS

Our EZ-Glue case and tray sealing equipment is designed to receive an erected, loaded box and securely seal the top using hot melt adhesive. The process begins when the case indexes from the conveyor and is positioned by a box stop before entering the machine. As the box transfers through the unit, the front and rear minor flaps are first tucked in. Hot melt glue is then applied to these minor flaps simultaneously as the major flaps are folded over the top of the case. Finally, the sealed case passes beneath a set of compression rollers to ensure a strong, permanent bond on the case top.

Videos

EZ Glue Case Max Mechanical Rates:

CS-FB (Flight Bar): 40 cycles per minute

CS-BNB (Bag-in-Box):22 cycles per minute

CS-BD (Belt Drive): 22 cycles per minute