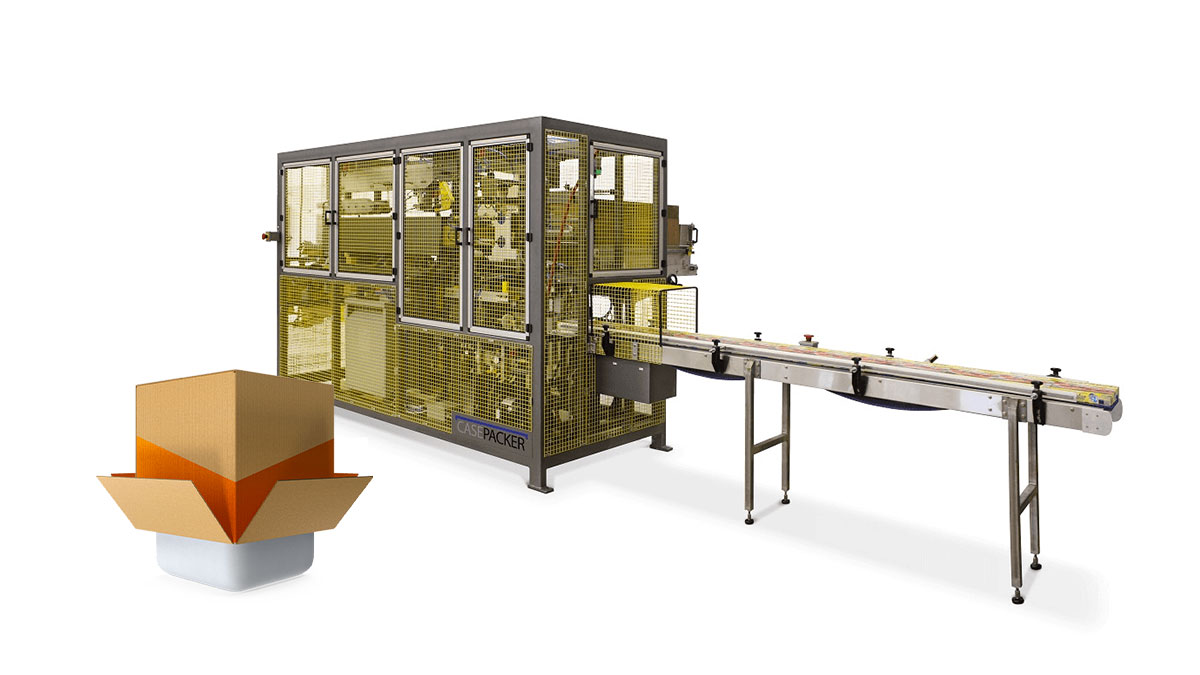

BOTTOM LOAD CASE PACKER

CASE FORMING AND LOADING MACHINE

Our compact automated case packing systems (which form, load, and seal) are engineered to completely eliminate manual labor from the entire case loading and sealing process. These flexible packers are manufactured to meet your specific production requirements, capable of handling a wide variety of products while significantly increasing overall productivity.

Videos

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area

BOTTOM LOAD CASE PACKER

CASE FORMING AND LOADING MACHINE

Our compact automated case packing systems (which form, load, and seal) are engineered to completely eliminate manual labor from the entire case loading and sealing process. These flexible packers are manufactured to meet your specific production requirements, capable of handling a wide variety of products while significantly increasing overall productivity.

Videos

- Product staging and loading area

- Servo loading mechanism

- Case erector

- Quick size change-over

- Heavy duty, welded tubular steel frame

- Venturi vacuum technology

- Omron PLC

- Color touch screen user interface allowing adjustment and full access to all functions & timing of machine

- 2” or 3” wide tape head or Nordson ProBlue glue system

- Low product and no product detectors on infeed

- Interlocked safety gates or doors

- Auto-idler

- Light stack and audible low hopper alarm

- Utility blow out air line with nozzle

- All electric controls

- STEEL-IT silver grey paint with all moving parts painted bright yellow

- 24 VDC control voltage

- On-line detailed operation manual accessible through HMI

- Product staging and loading area