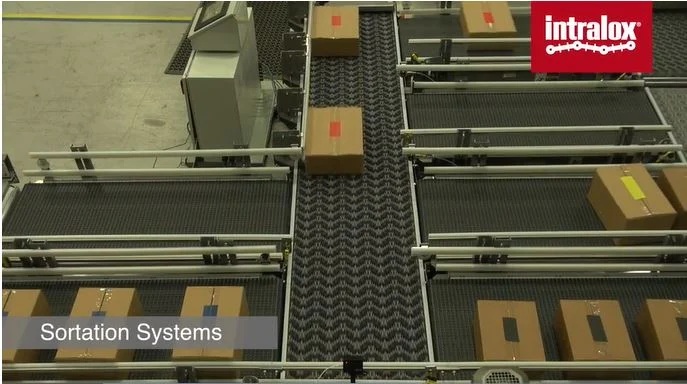

ARB Conveyor Diverters

Product Diverting Conveyance

ARB Conveyor Diverters offer a significant advantage in material handling by accurately diverting products without relying on complex controls or numerous moving parts. This streamlined design contrasts sharply with traditional methods, allowing ARB conveyor diverters to effectively replace bulky and often maintenance-intensive equipment such as pop-up transfers, transfer tables, and right-angle transfers, leading to simplified layouts, reduced maintenance costs, and improved operational efficiency.

Benefits of ARB Conveyor Systems with Conveyor Diverters:

- Enhanced Product Routing: Precise diversion capabilities optimize product flow and reduce bottlenecks.

- Reduced Maintenance: Fewer moving parts minimize downtime and maintenance costs.

- Simplified System Design: Streamlined layouts optimize floor space and improve accessibility.

- Increased Operational Efficiency: Smooth and reliable product handling enhances productivity.

- Cost Savings: Lower maintenance and reduced equipment requirements translate to significant cost savings.

- Flexible Applications: ARB conveyor diverters are adaptable to various industries, including packaging, distribution, and manufacturing.

Applications:

- Sorting and diverting products to different packaging lines.

- Merging and diverting products for order fulfillment.

- Automated distribution centers.

- Redirecting products to quality control stations.

When seeking advanced material handling solutions that prioritize precision, efficiency, and cost-effectiveness, consider the advantages of ARB conveyors and their integrated conveyor diverters. These systems offer a significant leap forward in optimizing product flow and streamlining operations.

Key Features:

- Safer than pushers and plows as they have no exposed moving parts

- Can be placed on close centers for tight sorting or diverting requirements

Options:

- Small foot print, 120 ppm

- low maintenance

- gentle handling

ARB Conveyor Diverter

Product Diverting Conveyance

ARB Conveyor Diverters offer a significant advantage in material handling by accurately diverting products without relying on complex controls or numerous moving parts. This streamlined design contrasts sharply with traditional methods, allowing ARB conveyor diverters to effectively replace bulky and often maintenance-intensive equipment such as pop-up transfers, transfer tables, and right-angle transfers, leading to simplified layouts, reduced maintenance costs, and improved operational efficiency.

Benefits of ARB Conveyor Systems with Conveyor Diverters:

- Enhanced Product Routing: Precise diversion capabilities optimize product flow and reduce bottlenecks.

- Reduced Maintenance: Fewer moving parts minimize downtime and maintenance costs.

- Simplified System Design: Streamlined layouts optimize floor space and improve accessibility.

- Increased Operational Efficiency: Smooth and reliable product handling enhances productivity.

- Cost Savings: Lower maintenance and reduced equipment requirements translate to significant cost savings.

- Flexible Applications: ARB conveyor diverters are adaptable to various industries, including packaging, distribution, and manufacturing.

Applications:

- Sorting and diverting products to different packaging lines.

- Merging and diverting products for order fulfillment.

- Automated distribution centers.

- Redirecting products to quality control stations.

When seeking advanced material handling solutions that prioritize precision, efficiency, and cost-effectiveness, consider the advantages of ARB conveyors and their integrated conveyor diverters. These systems offer a significant leap forward in optimizing product flow and streamlining operations.

Key Features:

- Safer than pushers and plows as they have no exposed moving parts

- Can be placed on close centers for tight sorting or diverting requirements

Options:

- Small foot print, 120 ppm

- low maintenance

- gentle handling