Z.Zag Palletizer

Robotic Case Palletizing & Depalletizing

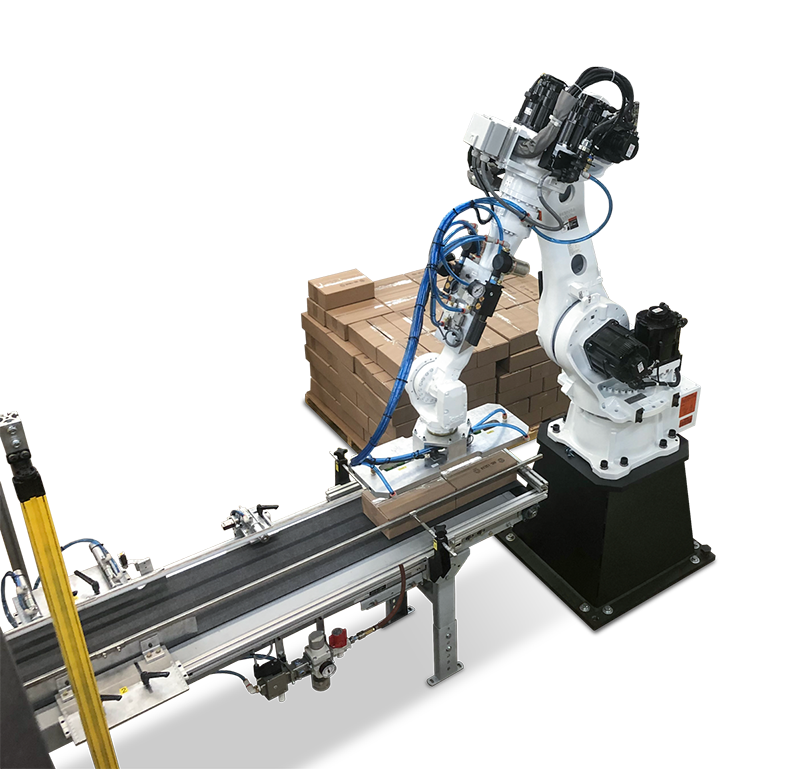

We specialize in end-of-line robotic palletizing systems for cases, trays, bags, containers, and more. Eliminate the risks associated with manual labor and automate your pallet loading and unloading processes. We deliver custom-engineered automated palletizing solutions tailored to the specific needs of your application, floor plan, and budget.

A robotic palletizing system is a device that uses a robotic arm to stack and arrange items on a pallet. The system can handle various items, such as boxes, bags, cans, bottles, or crates.

Components of the System:

The system consists of four main components: a robotic arm, an end-of-arm tool (gripper), a conveyor, and a control system.

-

The robotic arm is the component that moves and rotates to pick up and place the items.

-

The end-of-arm tool (gripper) attaches to the end of the arm and grasps the items using suction cups, clamps, or magnets.

-

The conveyor transports the items to and from the palletizing area.

-

The control system coordinates the movements and actions of the machine based on a predefined program or manual input.

Videos

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.

Z.Zag Palletizer

Robotic Case Palletizing & Depalletizing

We specialize in end-of-line robotic palletizing systems for cases, trays, bags, containers, and more. Eliminate the risks associated with manual labor and automate your pallet loading and unloading processes. We deliver custom-engineered automated palletizing solutions tailored to the specific needs of your application, floor plan, and budget.

A robotic palletizing system is a device that uses a robotic arm to stack and arrange items on a pallet. The system can handle various items, such as boxes, bags, cans, bottles, or crates.

Components of the System:

The system consists of four main components: a robotic arm, an end-of-arm tool (gripper), a conveyor, and a control system.

-

The robotic arm is the component that moves and rotates to pick up and place the items.

-

The end-of-arm tool (gripper) attaches to the end of the arm and grasps the items using suction cups, clamps, or magnets.

-

The conveyor transports the items to and from the palletizing area.

-

The control system coordinates the movements and actions of the machine based on a predefined program or manual input.

Videos

Features:

- Highly versatile, the Z.Zag robotic palletizer is ideal for case palletizing, bag palletizing, order picking and many logistical tasks for end-of-line or distribution center automation.

- High-performance, 5-axis robot with 80 kg payload capacity.

- Impressive 3,291 mm vertical reach, combined with 2,061 mm horizontal reach, enables palletizing loads up to 2,413 mm tall.

- Internally routed airlines and cables from base to end-of-arm tool maximize reliability.

- Cable installation tube in the base of the robot facilitates fieldbus routing to the robot upper arm and/or gripper.

- NSF-H1 certified food-grade lubricant option available for food or consumer product packaging environment.

- Compact base and slim-arm design of the MPL80 II is ideally suited for minimum floorspace installation requirements.

- Highly customizable to each palletizing system.