POPLOK

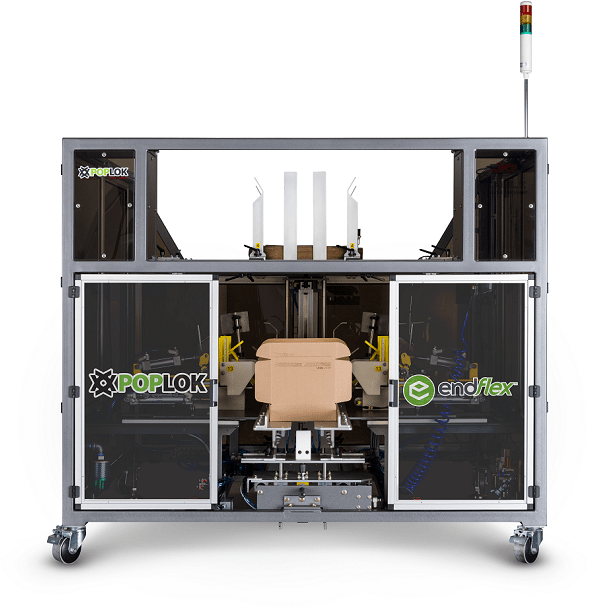

tray forming machine

Our family of fold-and-tuck tray forming machines is engineered for the automatic creation of display trays and shippers. This efficient former can automatically assemble die-cut blanks at speeds reaching up to 1,200 trays per hour. This technology is commonly applied across two primary uses:

-

Shippers & Mailers: Perfect for e-commerce and direct-to-consumer delivery, the machine converts flat die-cut blanks into secure, finished lidded trays that streamline mailing operations and significantly reduce the need for manual assembly labor.

-

Retail Display: The former has the versatility to produce a wide range of presentation trays, from simple flat-bottom containers to complex 5-tuck trays featuring back display walls and custom inserts. Stop forming corrugated trays by hand—it’s time to invest in an automatic tray forming solution!

Videos

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

POPLOK

tray forming machine

Our family of fold-and-tuck tray forming machines is engineered for the automatic creation of display trays and shippers. This efficient former can automatically assemble die-cut blanks at speeds reaching up to 1,200 trays per hour. This technology is commonly applied across two primary uses:

-

Shippers & Mailers: Perfect for e-commerce and direct-to-consumer delivery, the machine converts flat die-cut blanks into secure, finished lidded trays that streamline mailing operations and significantly reduce the need for manual assembly labor.

-

Retail Display: The former has the versatility to produce a wide range of presentation trays, from simple flat-bottom containers to complex 5-tuck trays featuring back display walls and custom inserts. Stop forming corrugated trays by hand—it’s time to invest in an automatic tray forming solution!

Videos

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI