Future-Proofing Your Production Line: The Strategic Advantage of Next-Generation Sanitary Conveyor Technology

In today’s fast-paced manufacturing world, agility is no longer a luxury—it’s a requirement. As food safety standards tighten, labor shortages grow, and product SKUs multiply, investing in next-generation sanitary conveyor technology is one of the most strategic decisions a facility can make to stay competitive and future-ready.

The Future Isn’t Optional—It’s Operational

Sanitary conveyor systems used to be purely about compliance. Today, they’re engineered for adaptability, automation, and performance—all while meeting the strictest hygiene regulations. Choosing the right system means you’re not just checking a box for today—you’re preparing your production line to evolve with industry shifts and market demands.

Design Features That Future-Proof Your Facility

- Modularity & Scalability: Modern sanitary conveyors like those from NCC Automated Systems are modular by design, allowing quick reconfiguration or expansion as your production needs grow.

- Superior Sanitation Design: Features like toolless belt removal, sloped surfaces, and minimal horizontal ledges reduce harborage points and speed up cleaning and inspection time.

- Compatible With Robotics & Automation: Built with integration in mind, these systems are ideal for facilities transitioning to vision systems, robotic pick-and-place, and data-tracked QA processes.

- Durability With Cleanability: Stainless steel and FDA-compliant materials are standard, offering long-term operation with minimal maintenance downtime.

Why It Matters: The Strategic Advantage

- Lower Long-Term Costs: By reducing cleaning labor, avoiding contamination-related downtime, and enabling automation, modern systems pay for themselves faster.

- Faster Changeovers: Minimizing downtime between batches or product types gives your facility more throughput flexibility and SKU responsiveness.

- Meeting Retail & Regulatory Demands: Retailers and auditors are increasingly looking at equipment—not just SOPs. Your conveyor system is part of your food safety program.

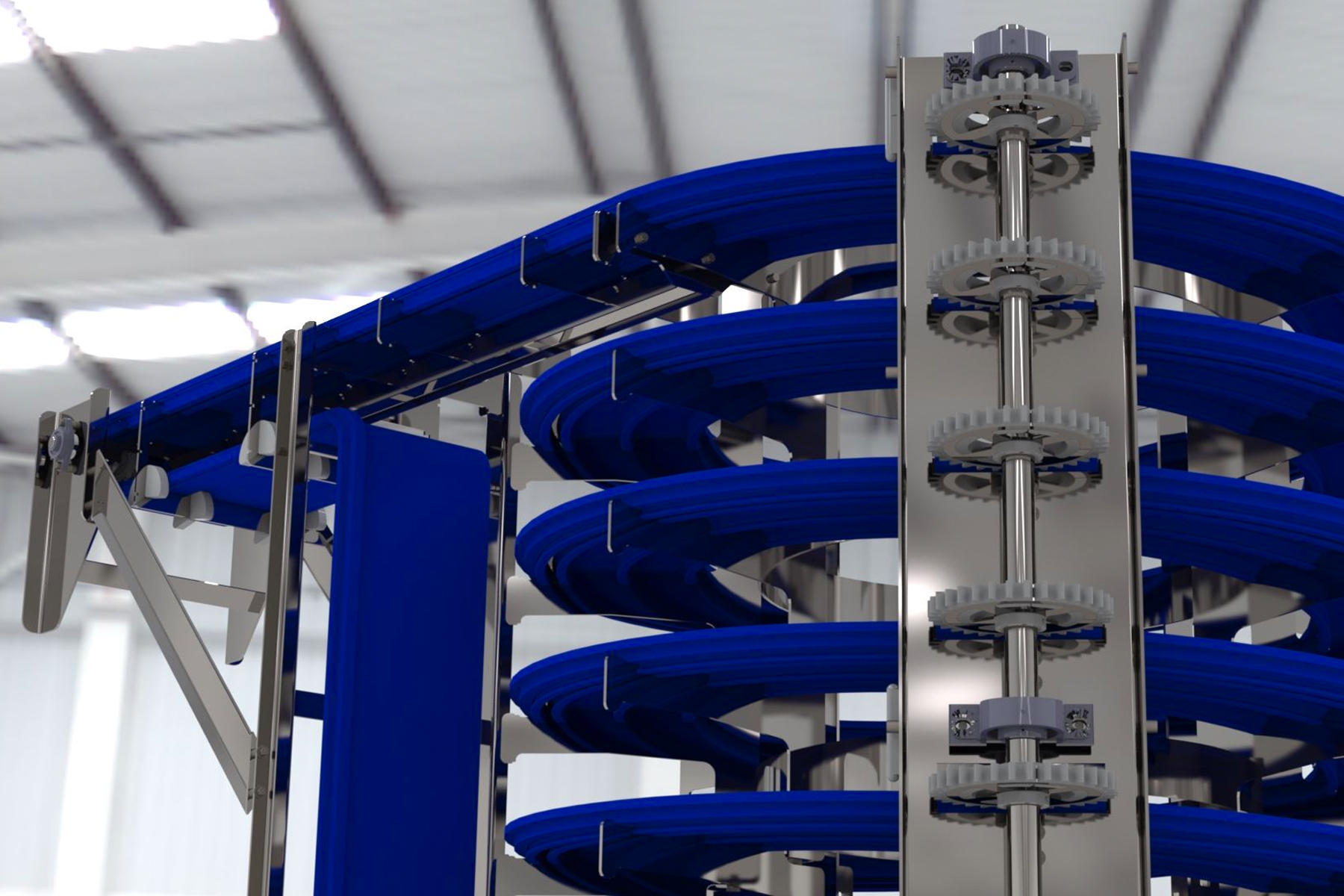

NCC’s Next-Gen Sanitary Conveyor Lineup

NCC offers a range of USDA-accepted, washdown-ready conveyors including:

- SideDrive Sanitary Spiral Conveyors

- Product Spreader and Combiner Conveyors

- Modular Flat Belt & Table Top Conveyors

- High-Speed Check Weighing Conveyors

All systems are built to evolve with your operation and withstand rigorous, high-frequency sanitation cycles.

Design Smarter with NCC’s Experts

Whether you’re upgrading a single line or building a facility from scratch, the team at NCC can help you integrate a conveyor system that’s not only sanitary—but scalable and smart.

📩 Contact info@nccas.com to get started on your next-generation production line.