Spiral Conveyors in Sanitary Food Production: How They Work & Why They Matter

In many food manufacturing environments—particularly in frozen food, baked goods, and ready-to-eat meal production—moving product efficiently and cleanly between processes is a key challenge. When space is tight and hygiene standards are high, spiral conveyors are often the most practical solution.

This article explores how spiral conveyors work, their benefits in food production, and why systems using Intralox belting are well-suited for sanitary applications.

What Is a Spiral Conveyor?

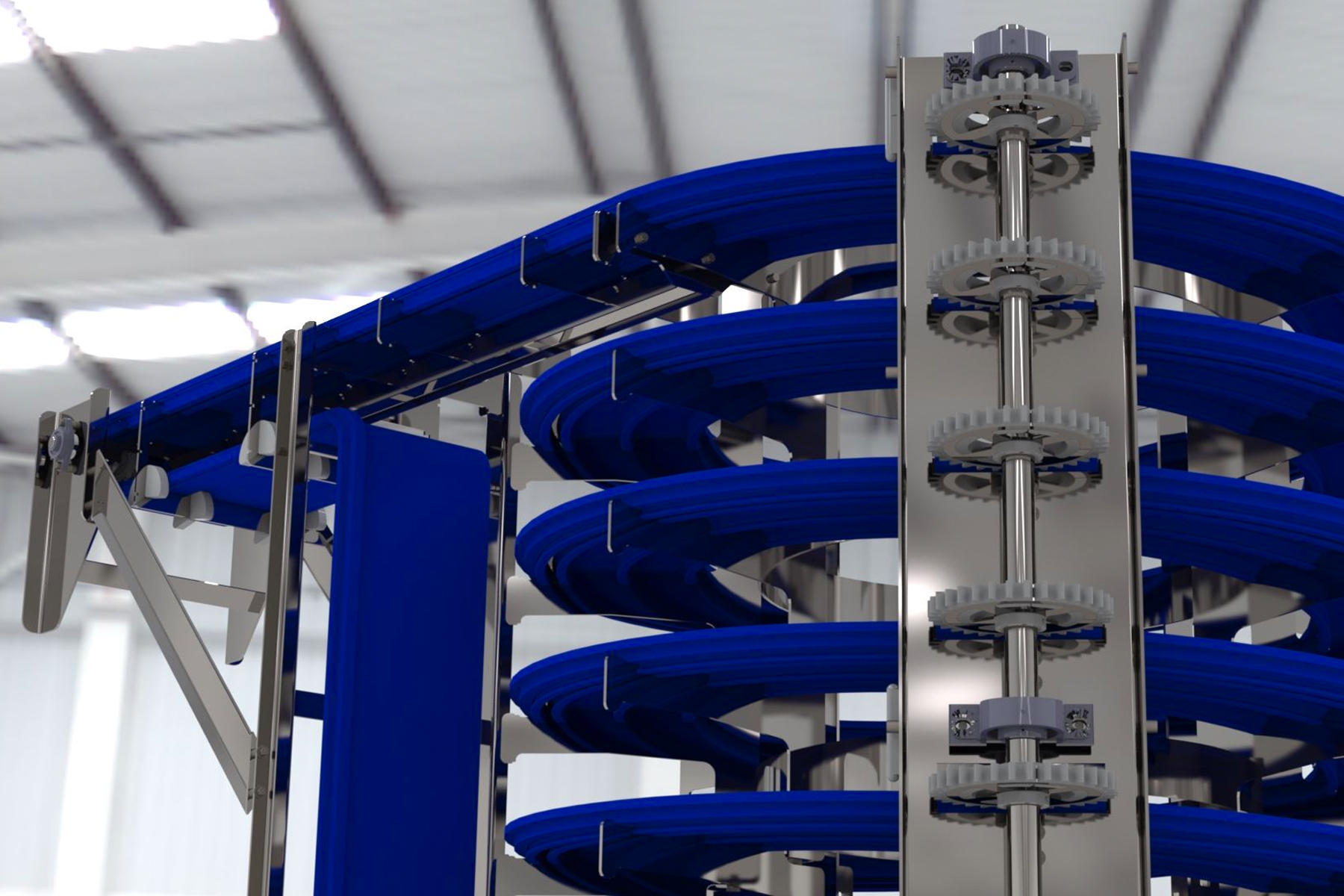

A spiral conveyor is a compact conveyor system that moves products vertically in a continuous, spiraling path. Instead of running a long incline conveyor that consumes linear floor space, spiral conveyors stack the path upward or downward in a tight spiral—helping manufacturers save space while keeping production lines flowing smoothly.

They’re often used to:

- Elevate or lower products between equipment or floors

- Provide cooling or curing dwell time

- Accumulate product during upstream or downstream delays

How Spiral Conveyors Work

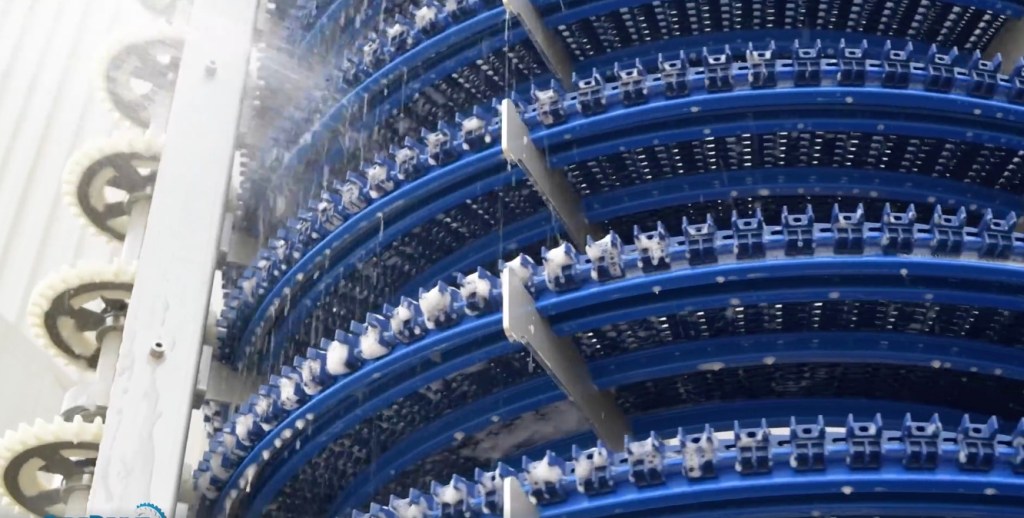

Spiral conveyors operate using a continuous belt or modular plastic chain, guided around a central rotating drum or tower. In this case, the system uses Intralox modular plastic belting, which wraps around the central core in multiple revolutions.

The belt is driven either by a friction drum or sprockets and is supported by rails that maintain its spiral shape and allow it to carry product gently up or down the path.

Here’s a simplified breakdown:

- Product enters the conveyor at the bottom or top

- The belt rotates in a spiral path, powered by a motor

- As the belt moves, it carries the product up or down depending on flow direction

- The product exits at the desired elevation, ready for the next stage of processing

The entire system is mounted within a compact footprint, making it ideal for tight floor plans or multi-level processing environments.

Why Intralox Belting?

This particular spiral conveyor system uses Intralox modular plastic belting, which is widely recognized in the industry for its sanitary design, durability, and ease of cleaning. Advantages include:

- Open, hygienic surfaces that reduce product buildup and improve drainage

- High-impact resistance for rugged food production environments

- Tool-less belt removal for fast sanitation and maintenance

- Durable, low-friction design that minimizes product damage and belt wear

Intralox belts are fully compatible with high-pressure washdown environments and are often selected for facilities that operate under FDA, USDA, or GFSI standards.

Applications in Food Manufacturing

Spiral conveyors are especially useful in food applications where the product requires rest time, air cooling, or drying before the next step in the production line. Some examples include:

- Bakery: Products such as breads, pastries, and cookies can be cooled as they move along the spiral, allowing them to stabilize before packaging or further handling.

- Frozen Foods: Spiral conveyors are used to move trays, pouches, or flow-wrapped items to blast freezers or cold storage areas without long, sloped conveyors taking up production space.

- Meat & Protein: Products such as vacuum-sealed meats or poultry can be elevated or staged for curing or cooling in controlled environments.

- Ready-to-Eat: Managing dwell time for products that require stabilization, curing, or air cooling.

- Packaged Goods: When used with packaged items, spiral conveyors can provide accumulation or buffering between fast and slow sections of the line.

Cooling, Curing & Resting Applications

In some food lines, spiral conveyors serve more than just a transport role—they function as process conveyors, helping manage:

- Cooling of baked or cooked products before packaging

- Curing or resting for doughs, meats, or processed foods

- Drying or airflow exposure for certain ingredients

Because the conveyor path can span dozens of revolutions, operators can adjust dwell time simply by changing belt speed or spiral length.

Easy Washdown and Cleanability

Spiral conveyors used in food production must be easy to clean—and systems built with Intralox belting and open stainless-steel frames are especially hygienic:

- Open-frame construction minimizes water and debris retention

- No hidden surfaces or fasteners in product zones

- Sloped surfaces for drainage

- Fast access for sanitation crews

- Supports CIP (Clean-In-Place) cleaning protocols in certain applications

These features reduce cleaning downtime and help meet regulatory compliance with less labor and fewer chemicals.

Space Efficiency and Layout Flexibility

One of the biggest advantages of spiral conveyors is their ability to move product vertically without taking up much space. Compared to inclined or bucket conveyors, spiral designs:

- Free up floor space for workers or other equipment

- Fit into tight layouts without sacrificing throughput

- Allow for multi-level integration (e.g., from ovens on one floor to packaging below)

They can be configured for upward or downward flow, and even multiple infeed/outfeed points when needed.

Spiral conveyors offer a versatile, compact, and sanitary method of product transport in food processing environments. Systems equipped with Intralox modular belting are particularly effective for applications involving cooling, curing, or vertical transport, especially where hygiene and washdown compatibility are required.

By reducing floor space needs and supporting safe, efficient product flow, spiral conveyors play a vital role in modern, high-compliance food production lines. For more information on spiral conveying systems—or any other sanitary conveyor solutions—you can reach out to NCC Automated Systems to discuss how their expertise can support your production goals – https://www.nccas.com/contact/.