SideDrive Spiral Conveyors

Spiral Compact Conveying – Sanitary

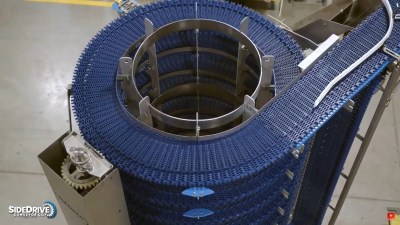

SideDrive’s sanitary spiral conveyors boast a small footprint thanks to a drumless, or cageless, design that takes space requirements out of the equation when it comes to turns and curves. This not only saves valuable space on the plant floor but also requires less materials and moving parts, keeping initial costs and total cost of ownership down to a minimum.

The sanitary Spiral Conveyor systems feature a plastic, modular belting. The USDA-compliant plastic material stands-up to repeated exposure to chemicals during cleaning.

The configuration possibilities are endless with SideDrive’s vertical conveyor systems. Inclines, declines and helical radius changes are no problem for our spiral conveyors and vertical conveyor systems. Our modular design provides the flexibility to ramp-up or scale-down production at any time.

Videos

Key Features:

- Drumless design ensures full sanitary conditions with less harborage areas

- Open, accessible belting and drive systems keeps maintenance easy and simple

- Saves space and costs by more than a third compared to direct drive systems

- Fast, efficient transport up and down between floors or levels, or over aisles

- Smooth, quick movement from stages—into a freezer from an oven and more

- Side drive, edge-driven technology from Intralox allows for minimal drive needs for turns and curves, whether going up or down

- Drumless spiral conveyor design is faster than traditional friction and positive drive conveyor systems

Options:

- The Most Sanitary Spiral Conveyor in the World

- Accommodates small foot print requirements

- Painted construction

- Stainless steel optional

- Table top belt (typical)

- Adapt to a variety of configurations and heights.

- Sprockets, combined with one or more drive motors, allow for continuous belt motion

SideDrive Spiral Conveyors

Spiral Compact Conveying – Sanitary

SideDrive’s sanitary spiral conveyors boast a small footprint thanks to a drumless, or cageless, design that takes space requirements out of the equation when it comes to turns and curves. This not only saves valuable space on the plant floor but also requires less materials and moving parts, keeping initial costs and total cost of ownership down to a minimum.

The sanitary Spiral Conveyor systems feature a plastic, modular belting. The USDA-compliant plastic material stands-up to repeated exposure to chemicals during cleaning.

The configuration possibilities are endless with SideDrive’s vertical conveyor systems. Inclines, declines and helical radius changes are no problem for our spiral conveyors and vertical conveyor systems. Our modular design provides the flexibility to ramp-up or scale-down production at any time.

Key Features:

- Drumless design ensures full sanitary conditions with less harborage areas

- Open, accessible belting and drive systems keeps maintenance easy and simple

- Saves space and costs by more than a third compared to direct drive systems

- Fast, efficient transport up and down between floors or levels, or over aisles

- Smooth, quick movement from stages—into a freezer from an oven and more

- Side drive, edge-driven technology from Intralox allows for minimal drive needs for turns and curves, whether going up or down

- Drumless spiral conveyor design is faster than traditional friction and positive drive conveyor systems

Options:

- The Most Sanitary Spiral Conveyor in the World

- Accommodates small foot print requirements

- Painted construction

- Stainless steel optional

- Table top belt (typical)

- Adapt to a variety of configurations and heights.

- Sprockets, combined with one or more drive motors, allow for continuous belt motion