Food plants require special sanitation methods throughout the manufacturing process, posing special challenges for the conveyors that move them. When food products are being handled in a plant, conveyors and other equipment must often meet specific design requirements set by government and/or other industry bodies. After the product is packaged – in either primary (individual) or secondary and tertiary packaging - manufacturing equipment may need to be periodically washed down, occasionally with high pressure water, steam, and/or chemicals to maintain a clean environment and mitigate contamination in the facility.

But, standard industrial-duty conveyors are not suitable for wet, humid, and corrosive environments. Applications in these settings require a different approach to conveying. Within those conveyor types that can handle these environments, there are two easily-confused options: sanitary and washdown.

But, standard industrial-duty conveyors are not suitable for wet, humid, and corrosive environments. Applications in these settings require a different approach to conveying. Within those conveyor types that can handle these environments, there are two easily-confused options: sanitary and washdown.

Sanitary Versus Washdown: What’s the Difference?

Not all conveyors that move food products are required to be truly sanitary. This is dependent on the food and process type, along with the stage in the manufacturing or packaging process. In many packaging applications, the conveyor will likely need to be washdown-compatible, but not necessarily “sanitary.”

This distinction is important, because virtually all sanitary conveyors are able to withstand high-pressure washdown with harsh chemicals, but not all washdown-compatible conveyors are sanitary. Case in point – a conveyor that uses chain conveying media can withstand a high-pressure washdown, but chain isn’t inherently sanitary, since it introduces thousands of crevices where particles and bacteria can accumulate.

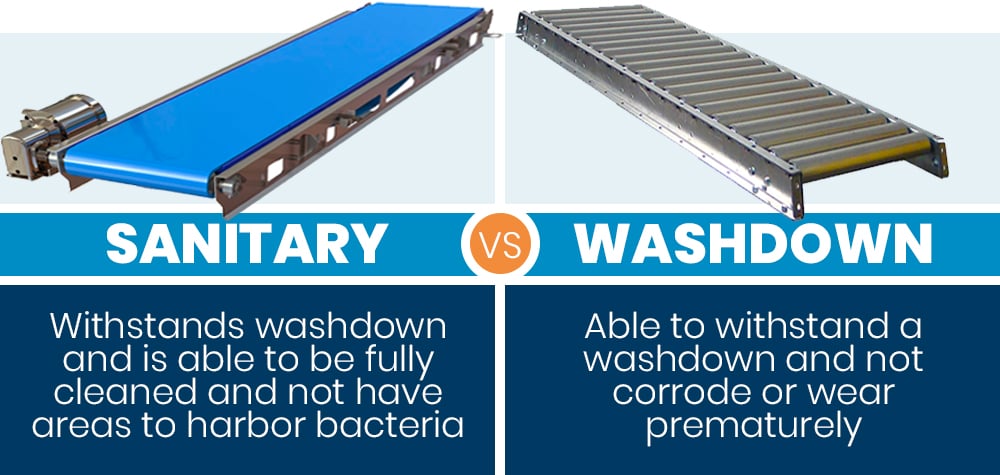

It really comes down to this: washdown applications are able to withstand frequent washdown without corroding or wearing prematurely, while sanitary applications are able to be fully cleaned and not have areas to harbor bacteria, and can withstand the same stringent conditions as a washdown application.

However, in either type of application – true sanitary or washdown-compatible – a stainless steel conveyor is typically the best solution. Various grades of stainless steel have been tested in a wide range of washdown conditions, and their resistance to corrosion is well-documented. Stainless steel materials are widely accepted (and even endorsed) by government and industry bodies that deal with washdown-compatible and sanitary applications for food and beverage manufacturing.

A Synopsis: Guidance and Regulations for Washdown and Sanitary Designs

Although there are many formal definitions of what “sanitary” or “washdown” designs entail, numerous government and industry bodies provide guidance on building equipment for both sanitary and washdown applications in the food industries. Below are some of the most common:

FDA: United States Food and Drug Administration – Publishes Current Good Manufacturing Practices to help ensure the safety of food and pharmaceuticals

USDA: United States Department of Agriculture – Offers two voluntary, fee-based equipment review and certification programs to the food processing industry: the Dairy Equipment Review Program and the Meat and Poultry Equipment Review Program.

EHEDG: European Hygienic Engineering & Design Group – A consortium of equipment manufacturers, food producers, suppliers to the food industry, research institutes and universities, public health authorities, and governmental organizations formed to promote

safe food by improving hygienic engineering and design in all aspects of food manufacture.

3-A SSI: 3-A Sanitary Standards Inc. – An independent, not-for-profit corporation dedicated to the mission of advancing food safety through hygienic equipment design. The membership consists of four associations: American Dairy Products Institute, International Dairy Foods Association, Food Processing Suppliers Association, and the International Association for Food Protection.

BISSC: Baking Industry Sanitation Standards Committee – Develops and publishes voluntary standards for the design and construction of bakery equipment which today are recognized as the definitive sanitation standards for equipment used in the baking industry.

Stainless Steel Pallet Conveyor Options for Washdown Applications

Conveyors for washdown and sanitary applications are typically made of stainless steel and plastic components to avoid rust and the contamination it can cause.

NCCAS has years of experience building both sanitary and washdown-compatible conveyors for the many industries, including; food, pharmaceutical, and chemical. We also know which conveyor designs will meet the requirements of a specific application. These are five options and their designation according to which environment they’re most suitable for in an automated manufacturing setting.

Gravity roller conveyors: Washdown or sanitary compatible

Gravity roller conveyors: Washdown or sanitary compatible

Gravity roller conveyors move products on a flat (with assistance) or declined plane. Solid rollers are required in order for the conveyor to be sanitary-compatible.

Powered roller conveyors: Washdown compatible

Powered roller conveyors: Washdown compatible

Powered roller conveyors are typically used for transporting cases, heavy pallets, or totes and can also be used for product accumulation. They can be designed to withstand washdown conditions by using solid rollers made of PVC or UHMW plastic. With this (expensive) design modification, powered roller conveyors are suitable for applications where there is no direct food contact, such as end-of-line packaging and sorting.

Powered roller conveyors are typically used for transporting cases, heavy pallets, or totes and can also be used for product accumulation. They can be designed to withstand washdown conditions by using solid rollers made of PVC or UHMW plastic. With this (expensive) design modification, powered roller conveyors are suitable for applications where there is no direct food contact, such as end-of-line packaging and sorting.

Drag chain conveyors: Washdown compatible

Drag chain conveyors: Washdown compatible

Drag chain conveyors can be manufactured with metal roller chains in various steel materials and are used for transporting large, bulky pallets. With stainless steel construction and chain transport media, they can withstand washdown conditions. However, these conveyors aren’t suitable for applications where bacteria growth is a concern.

Plastic modular belt conveyors: Sanitary or washdown compatible

Plastic modular belt conveyors: Sanitary or washdown compatible

Stainless steel conveyors that use plastic modular belts have become the industry-standard for food, beverage, and even pharmaceutical processing plants, since belts made of plastic can withstand even the harshest washdown conditions. Plastic modular belts are easily taken apart, when necessary, without removing the entire belt, so both the belt and conveyor structure can be deep-cleaned and sanitized. Depending up the specific design, these can achieve Sanitary levels. Read more in our post about this versatile conveyor.

Stainless steel conveyors that use plastic modular belts have become the industry-standard for food, beverage, and even pharmaceutical processing plants, since belts made of plastic can withstand even the harshest washdown conditions. Plastic modular belts are easily taken apart, when necessary, without removing the entire belt, so both the belt and conveyor structure can be deep-cleaned and sanitized. Depending up the specific design, these can achieve Sanitary levels. Read more in our post about this versatile conveyor.

NCC Automated Systems has over 30 years of experience building conveyors for the food, beverage, pharmaceutical, and other industries where cleanliness is a necessity. Our food industry expertise means we understand the need for easy-to-clean and washdown-compatible solutions, with zero margin for error.

We work with you to develop an incredibly detailed and accurate proposal based on all the factors of your application: product being transferred, special handling requirements, transfer path, intermediate and end processes, accumulation needs, and more. With this detailed plan, we build the conveyor that best fits your application, on time and on budget.

Let us help with your next project. Contact us today for a free consultation!

Leave a Comment