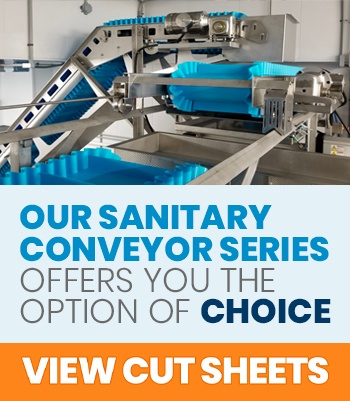

When we take a look at an application, we’re also assessing what level of sanitary design the system requires.

Some equipment providers only offer one, low-level sanitary design. This could be due to their inexperience designing for a high wash down environment or because of they do not supply to food producers. There are also other companies out there that supply only high-level sanitary equipment, so you may be paying for sanitary design features that you do not need for your application. The key is to understand the sanitary design that is right for you.

Here’s an example: say you have a raw cheese application. We come in, review the application. We ask critical questions: how often the system is washed? what types of chemicals are used? what sanitation regulations are there and what design features are necessary in order to meet those regulations? A food processing application is going to require a higher level of sanitation than say, a solar panel assembly line.

A thorough sanitary design assessment is the first step to finding out which sanitary design is right for you, so that the solution cost is a reflection of your specific sanitary design application.

Leave a Comment