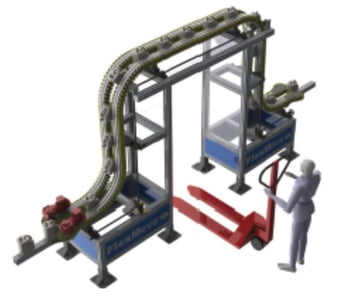

Our Wedge, or “Gripper,” Elevator conveyor is the perfect solution to easily and quickly elevate products, cartons, totes and cases within your automation system. It’s built for simplicity and speed. Here’s everything you need to know about our Wedge Elevator.

It’s adjustable

It’s adjustable

The Wedge Elevator is adjustable to be used with products of various sizes and shapes including boxes, cans, bottles, and plastic containers. It can also change product orientation, such as flipping upside down or 180 degrees, for transport. The wedge elevator has two specialty chains situated parallel to each other. These chains can be quickly adjusted using a manual conveyor positioner for quick product size changeover on the same automation line.

- 45 mm, 65 mm and 85 mm belt widths

- Minimum lower height: 457 mm (18 in)

- Maximum upper height: 6096 mm (240 in)

It has a small footprint

It has a small footprint

This conveyor saves space by vertically lifting or lowering a product quickly and simply. It “grabs” the item from the starting point, a platform or another conveyor, and "squeezes" the sides of the product or box being moved to hold it as it ascends or descends.

Its weight capacity: 200 pounds total

Its weight capacity: 200 pounds total

The two opposing chains of the Wedge Elevator are able to lift products, boxes, or containers that weigh generally less than 4.5 kg (10 lbs) each. However, with very sturdy products, this can be increased to 9 kg (20 lbs). The Wedge Elevator is not suitable for wet or heavy products. Total product weight on the Wedge Elevator conveyor should not exceed 90 kg (200 lbs).

Products should be able to withstand some slight pressure on either side where they have contact with the conveyor’s flexible wedge “fingers,” since the pressure is what keeps the products from slipping. Note that we have three different chain fingers available - from gentle to sturdy.

It has a rapid transfer speed

It has a rapid transfer speed

The Wedge Elevators' rapid transfer rates make them ideal for continuous high-capacity operations such as packaging lines. Because it doesn’t require products to slow or stop to be transferred, this elevator is a simple addition to the automation process that doesn’t typically require much rework of the line to incorporate. It can operate at up to 52.2 m/min (171 ft/min).

Made with aluminum and stainless steel

Made with aluminum and stainless steel

Available in aluminum or stainless steel, the Wedge Elevator can meet the stringent hygiene standard required for medical and cosmetic packaging. It is not considered a sanitary conveyor, but can be washed without risk of bacterial build-up.

Guarding keeps operators safe

Guarding keeps operators safe

Operator safety is important for both positive employee experience and efficient manufacturing. Clear Lexan (polycarbonate) guarding is included for operator safety around the transfer points and elevator itself.

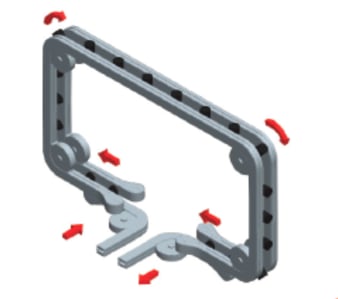

Configurable in four ways

Configurable in four ways

Our wedge conveyor can be configured in the following shapes – S, C, N (U) and O.

S Type Configuration

The product is elevated or lowered along a straight path from one horizontal platform or conveyor to another at a new level. This is the most common wedge configuration.

C Type Configuration

The product is elevated or lowered while changing the orientation or flipping the product. It starts at one level and rises or lowers the product to another, accomplishing the product positioning change.

N (U) Type Configuration

The product is elevated and lowered (opposite for U shape) to allow for clearance below the conveyor. This clearance may be needed to allow for traffic through the conveyor or to accommodate another conveyor or piece of equipment to pass through..

O Type Configuration

In this configuration, the product follows the loop, tipped upside down and conveyed back near the infeed. This can be used to dry products or to empty bottles/containers before the next part of the process.

Wedge Elevators are easy to construct, lightweight and have compact footprints. Its rapid transfer rate makes it ideal for use in continuous, high capacity operations. Contact us today at (215) 721-1900 to see if the Wedge Elevator conveyor is a good fit for your automation system.

Leave a Comment