Conveyors for washdown applications are typically made of stainless steel and plastic components to minimize rust and the contamination it can cause. This is especially true when it comes to conveying foods, pharmaceuticals, and nutraceuticals. But the conveying medium is also an important piece of equipment, determining whether a conveyor is washdown-compatible.

We have more than 30 years of experience building both sanitary and washdown-compatible conveyors for the many industries, including food, pharmaceutical, and nutraceutical, and we know which conveyor designs will meet the requirements of a specific application. So we’ve put together a summary of the six most common types of conveyors used for transporting pallets in washdown environments.

Roller based conveyors

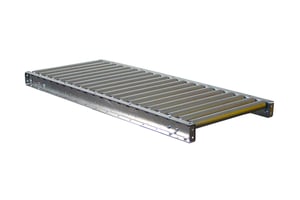

Gravity roller conveyors

Gravity roller conveyors

Simpler than powered roller conveyors, gravity roller conveyors move products on a flat (with assistance) or on a declined plane. Without a mechanism to power the rollers, there are fewer components and areas where particles and bacteria can accumulate. But like powered roller designs, solid rollers are required in order for the conveyor to be washdown-compatible.

Simpler than powered roller conveyors, gravity roller conveyors move products on a flat (with assistance) or on a declined plane. Without a mechanism to power the rollers, there are fewer components and areas where particles and bacteria can accumulate. But like powered roller designs, solid rollers are required in order for the conveyor to be washdown-compatible.

Key features include:

- Non-powered for transport on a flat or declined plane

Available options include:

- Custom roller diameters and lengths available

- Multiple bearing and shaft options

- Solid rollers made of PVC or UHMW plastic available for washdown applications

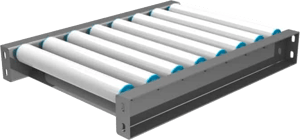

Powered roller conveyors

Powered roller conveyors

In powered roller conveyors, rollers – driven by belts, chains, or line shafts – serve as the conveying media. Powered roller conveyors are typically used for transporting cases or heavy pallets and can be used for product accumulation. In their standard form, they’re not typically recommended washdown-compatible (though they can be used), since particles and water can penetrate into the hollow rollers and allow bacteria to grow. This contamination can be distributed by the rollers across the whole conveyor line, causing significant problems with cleanliness.

In powered roller conveyors, rollers – driven by belts, chains, or line shafts – serve as the conveying media. Powered roller conveyors are typically used for transporting cases or heavy pallets and can be used for product accumulation. In their standard form, they’re not typically recommended washdown-compatible (though they can be used), since particles and water can penetrate into the hollow rollers and allow bacteria to grow. This contamination can be distributed by the rollers across the whole conveyor line, causing significant problems with cleanliness.

However, stainless steel pallet conveyors can be designed to withstand washdown conditions by using solid rollers made of PVC or UHMW plastic. With this design modification, powered roller conveyors are suitable for applications where there’s no direct food contact, such as end-of-line packaging and sorting.

Key features include:

- Suitable for a wide range of transport and accumulation applications

Available options include:

- Custom roller diameters and lengths available

- Multiple bearing and shaft options

- Solid rollers made of PVC or UHMW plastic available for washdown applications

Chain based conveyors

Drag chain conveyors

Drag chain conveyors

Drag chain conveyors can be manufactured with either metal roller chains or plastic chains and are used for transporting large, bulky pallets. With stainless steel construction and chain transport media, they can withstand washdown conditions. However, drag chain conveyors – even washdown-compatible versions – introduce numerous surfaces and “nooks and crannies” where particles and bacteria can become trapped, and so aren’t suitable for applications where bacteria growth is a concern.

Drag chain conveyors can be manufactured with either metal roller chains or plastic chains and are used for transporting large, bulky pallets. With stainless steel construction and chain transport media, they can withstand washdown conditions. However, drag chain conveyors – even washdown-compatible versions – introduce numerous surfaces and “nooks and crannies” where particles and bacteria can become trapped, and so aren’t suitable for applications where bacteria growth is a concern.

Key features include:

- 2 or 3 strands of roller chain

- Washdown-compatible

Available options include:

- Heavy duty option for pallet and tote handling applications

Plastic Modular Belt based conveyors

The most common conveying media for sanitary and washdown environments is the plastic modular belt. The primary reason for this is their cleanability. Plastic modular belts can withstand cleaning via high-pressure washdown and are easy to take apart for more extensive cleaning and sanitizing, providing excellent protection against bacterial contamination.

Plastic modular belts are also available in a wide variety of materials, including polyethylene (PE), polypropylene (PPE), polyacetal (POM, or acetal), polyamide (PA, or nylon), as well as special versions to provide characteristics such as resistance to extreme heat, non-stick surfaces, or resistance to cuts. And because they’re assembled in a bricklay pattern, plastic modular belts are also easy to configure to fit the application’s specific length and width requirements, as well as other application-specific customizations.

Plastic modular belt conveyors

Plastic modular belt conveyors

Stainless steel conveyors that use plastic modular belts have become the industry-standard for food, beverage, and even pharmaceutical processing plants, since belts made of plastic can withstand even the harshest washdown conditions. And plastic modular belts are easy to take apart, when necessary, many times without removing the entire belt, so both the belt and conveyor structure can be deep-cleaned and sanitized.

With their easy-to-clean design and lack of rollers or chains, some plastic modular belt conveyors nearly eliminate the risk of bacterial contamination. And with a wide range of belting options, NCC Automated Systems can provide stainless steel conveyors with plastic modular belts for loads up to 6000 pounds.

Key features include:

- Washdown-compatible

- Easy to clean

- Extremely reliable conveyor media

Available options include:

- Hundreds of belting styles available

- Can be built to suit all types of processing environments

Multi-strand conveyors

Multi-strand conveyors

Another type of conveyor that can use plastic modular belting as the conveying media is the multi-strand conveyor. This conveyor is built using stainless steel components to make it washdown-compatible. Multi-strand designs are typically used for transporting very wide pallets or when access to the bottom of the pallet is needed.

Another type of conveyor that can use plastic modular belting as the conveying media is the multi-strand conveyor. This conveyor is built using stainless steel components to make it washdown-compatible. Multi-strand designs are typically used for transporting very wide pallets or when access to the bottom of the pallet is needed.

Key features include:

- Allows access to the bottom of a product or pallet

- Washdown-compatible

Available options include:

- Customizable to specific length and width requirements

- Can be center-driven or end-driven

Solid Urethane Belt Conveyor

Solid Urethane Belt Conveyor

Solid urethane belting has become the new standard in sanitary applications because of its operational efficiency, reliable, predictable drive performance, component wear, and improved yield. This technology combines flat, homogeneous thermoplastic material, and the positive drive feature of modular plastic belting with a unique drive engagement solution. This combination creates a tensionless belt system that eliminates the costs and complexities associated with managing a tensioned belt system.

Solid urethane belting has become the new standard in sanitary applications because of its operational efficiency, reliable, predictable drive performance, component wear, and improved yield. This technology combines flat, homogeneous thermoplastic material, and the positive drive feature of modular plastic belting with a unique drive engagement solution. This combination creates a tensionless belt system that eliminates the costs and complexities associated with managing a tensioned belt system.

Key features include:

Typically used on our PREMIUM Series conveyors, our sanitary design along with the solid urethene belting make cleaning and inspection easier and lead to a dramatic decrease in sanitation time and costs. Solid urethane belt conveyors are used in a wide variety of applications to meet a range of food-processing needs, including those in snack; fruit and vegetable; and meat, poultry, and seafood plants. Conveyor applications include straight conveyors, inclines, trough conveyors, conveyors with scrapers, z-elevators, bucket elevators, and cold environments. We work closely with the belting suppliers engineering department to verify the belt selection and to ensure that the conveyor has been designed and manufactured to meet or exceed of the design criteria.

Available options include:

- Straight conveyors

- Inclines

- Trough conveyors

- Conveyors with scrapers

- Z-elevators

- Bucket elevators

- Cold environments

Regardless of your application, NCC Automated Systems can help you find the right stainless steel conveyor for your exact requirements, with no compromises. Not only can we help you find the right solution, we can help you integrate it into your next project. Learn more about stainless steel conveyors and where they can be applied in our ebook, A Decision-Maker’s Guide to Using Stainless Steel Pallet Conveyors in Washdown Applications.

Leave a Comment